Novolex brand Shields is boosting production of recyclable mailers to meet growing demand for better solutions for online order fulfillment and other shipping

With demand increasing, Novolex ® brand Shields® is stepping up production of its innovative poly mailers to help companies ship their products more reliably and securely.

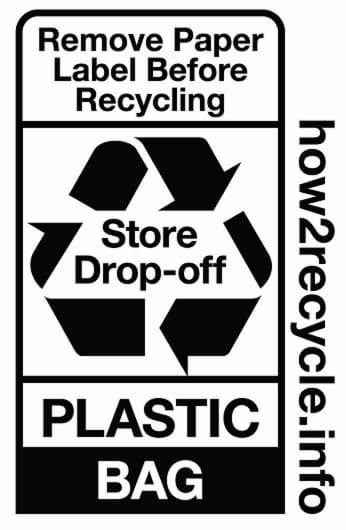

Manufactured in the USA, the Shields eCommerce mailer bag is durable, puncture resistant and waterproof. Its easy-to-use closure uses a secure, pressure-sensitive adhesive with an anti-static release liner. The mailer is also labeled with the How2Recycle®“store drop-off” label, which instructs consumers and businesses to bring mailers to participating retailers for recycling.

“The pandemic is creating an intense need for secure poly mailers manufactured dependably in the USA,” said Martin McDonough, Vice President of Sales for Shields. “We are increasing production of our high-quality mailers so we can help as many companies as possible ship their products more reliably and securely.”

Shields’ poly mailers are ideal for online order fulfillment as well as other shipping needs. They are offered in both generic colors and customized designs. Fast delivery is available because the poly mailers are stocked in both East Coast and West Coast fulfillment centers.

As a division of Novolex, Shields manufacturers the mailers as part of a broader corporate commitment to sustainability. For years, Novolex has operated two polyethylene recycling facilities that specialize in recycling plastic bags, wraps and other films. Along with Novolex’s recycling program, which accepts films recycled at “store drop-off” collection points, these actions contribute to greater circularity of plastic films.

Shields’ poly mailers come in a variety of sizes, including 7.5x9.5 inches, 9x12 inches, 10x13 inches, 12x15.5 inches and 14.5x19 inches. They are available for sale at https://www.shieldssecuritybags.com.

The poly mailers are among a wide variety of products offered by Shields Security Products that include bank deposit bags, shipping bags, coin bags and strap bags.

More recently, Shields’ plant in Yakima, Wash. began producing nearly 1 million medical isolation gowns per week to help hospital workers during the pandemic.

“At Novolex, we are always searching for innovative solutions in everything we do,” McDonough said. “For stepping up to manufacture PPE isolation gowns for the first time, the Association of Washington Business gave the Shields operation in Yakima its Innovation Award during the association’s National Manufacturing Week festivities. We’re very proud to have received this recognition.”

To learn more about Novolex and its many products, visit www.Novolex.com.

About Novolex

Novolex develops and manufactures diverse packaging and food service products that touch nearly every aspect of daily life for multiple industries ranging from grocery, food packaging, restaurant and retail to medical applications and building supplies. The Novolex family of brands provides customers innovative paper and plastic solutions for their business needs today while investing in research and development to engineer more sustainable choices for the future. With more than 10,000 employee families, Novolex operates 61 manufacturing centers and administrative offices in North America and Europe, including two world-class plastic film recycling facilities. To learn more about Novolex, visit www.Novolex.com.